- Homepage

- /

- Next-Generation Food Industry Valves: Precision, Hygiene, and Data-Driven Control

Next-Generation Food Industry Valves

Upgrade your food processing with Dolphin Fluidics' digitally native mechatronic valves. Ensure precision, hygiene, and data-driven efficiency. Compliant with FDA & 3-A standards.

The modern food and beverage industry faces a dual challenge: satisfying stringent hygiene standards while simultaneously boosting operational efficiency and process control. Traditional mechanical valves, long the industry standard, are reaching their limits.

They lack the precision, data integration, and intelligent control necessary to meet the demands of Industry 4.0. Decision makers in production and engineering now require a solution that not only manages fluid but also provides actionable data to optimize every stage of the process.

Dolphin Fluidics introduces a paradigm shift with its digitally native mechatronic food industry valves. We move beyond simple open-close mechanisms to offer a new standard in fluidic control. We provide the tools to eliminate costly inefficiencies, mitigate contamination risks, and unlock the full potential of your production lines.

The new standard in valves for the food industry: beyond mechanical control

For decades, the core technology behind food industry valves has remained largely unchanged. The absence of integrated data makes process monitoring, traceability, and predictive maintenance difficult, if not impossible. Furthermore, complex mechanical designs can create cleaning challenges, increasing the risk of biofilm buildup and contamination.

Our technology directly addresses these shortcomings. By defining a new, digitally native mechatronic standard, we empower you to:

- Achieve unprecedented precision: control flow rates, pressures, and dosing with digital accuracy, eliminating the guesswork and manual adjustments associated with pneumatic or manual valves.

- Leverage actionable data: our valves generate and manage critical operational data through serial, digital, and wireless connections, integrating seamlessly with your SCADA and plant management systems.

- Enhance hygienic security: designed from the ground up for sanitary applications, our solutions minimize hold-up volume and ensure cleanability, supporting your compliance with the strictest industry standards.

This is not an incremental improvement; it is a fundamental evolution in how fluid dynamics are managed, transforming a simple component into an intelligent node in your connected facility.

Discover more about our Food&Beverage Valves

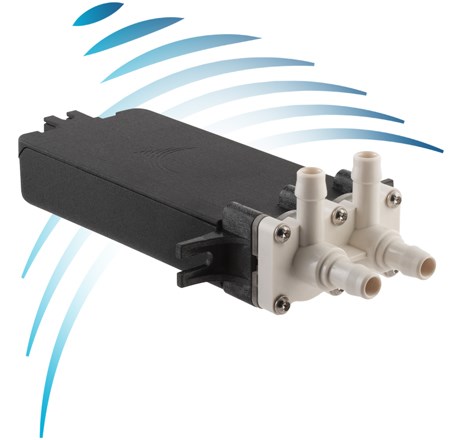

Types of smart valves for food applications

While the principles of valve design (like diaphragm or pinch) are established, their execution is what sets Dolphin Fluidics apart. Our mechatronic approach redefines the capabilities of each valve type, tailoring them for the specific demands of the food and beverage sector. Unlike a standard catalog, we provide integrated solutions designed for advanced automation and control.

Discover our food industry valves

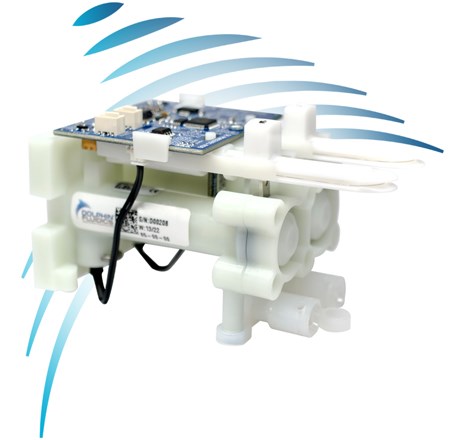

Custom Mechatronic Fluidic Systems

Many processes require more than a single valve. We specialize in developing integrated fluidic manifolds and systems that combine multiple functions—mixing, diverting, dosing, and sampling—into a single, compact, and intelligent unit. This approach reduces system complexity, minimizes dead legs, and provides centralized data and control for complex operations like Clean-in-Place (CIP) systems or multi-ingredient batching.

Why digitally native food industry valves are essential for modern processing

Adopting advanced valve technology is no longer just about gaining a competitive edge; it's about future-proofing your operations. For engineers and production managers focused on ROI and operational excellence, the benefits of a digitally native approach are clear and compelling.

Unmatched precision and contamination control

In food processing, consistency is key. Our electronically controlled valves offer digital precision that eliminates process drift. This means exact dosing for ingredients, consistent fill levels, and optimized flow rates, reducing product waste and ensuring quality. The hygienic design, compliant with rigorous standards, drastically lowers the risk of contamination, safeguarding your brand reputation and consumer safety.

Data-driven efficiency & process optimization

Are you tired of relying on reactive maintenance and manual process checks? Our valves are intelligent IoT devices. They provide real-time data on cycle count, pressure, flow, and internal diagnostics. This information feeds directly into your control systems, allowing you to:

- Predict maintenance needs: address potential issues before they cause costly downtime.

- Optimize CIP cycles: use data to verify cleaning effectiveness and potentially reduce water and chemical usage.

- Improve traceability: maintain a complete digital record of fluid paths and process parameters for every batch, simplifying audits and quality control.

Simplified compliance with FDA, 3-A, and EHEDG Standards

Compliance is non-negotiable. Our valves are engineered with materials and design principles that meet and exceed key industry standards, including FDA-approved materials and designs adhering to 3-A and EHEDG hygienic principles. This simplifies the validation process for your equipment and provides peace of mind that your facility operates at the highest level of safety and quality.

Reduced Total Cost of Ownership (TCO)

While the initial investment in advanced technology may be higher than for a simple mechanical valve, the TCO is significantly lower. Savings are realized through:

- Reduced product waste: thanks to superior accuracy.

- Lower energy consumption: compared to compressed air systems for pneumatic valves.

- Minimized downtime: due to predictive maintenance and high reliability.

- Streamlined operations: through automation and remote control.

Key applications for our advanced food processing valves

Dolphin Fluidics' technology is versatile and powerful, delivering transformative results across a wide range of applications within the food and beverage industry.

- Aseptic filling and dosing: achieve sterile, precise, and repeatable dosing of flavors, vitamins, and preservatives in dairy, juice, and liquid food products.

- Syrup and concentrate handling: accurately control high-viscosity fluids in beverage production, ensuring perfect consistency in every batch of soft drinks or coffee.

- CIP and SIP Systems: automate and optimize your cleaning and sterilization processes with intelligent valves that provide feedback on cycle completion and performance.

- Ingredient batching and mixing: create complex recipes with digital accuracy, ensuring product quality and minimizing operator error.

- Fermentation control: precisely manage the addition of nutrients and gases in brewing, dairy fermentation, and biotech applications.

Partner with Dolphin Fluidics for your digital transformation

Choosing the right component is a critical decision. It impacts your product quality, operational efficiency, and bottom line. At Dolphin Fluidics, we offer more than just a product; we offer a partnership. We work with your engineering teams to understand your unique challenges and design a fluid control system that meets your strategic goals.

Contact request

Thank you for your interest Error processing your request. Please retry or contact us.

)