- Homepage

- /

- Dolphin Fluidics shape memory alloy valves

Dolphin Fluidics shape memory alloy valves

Dive into the cutting-edge world of Shape Memory Alloy (SMA) Valves from Dolphin Fluidics, where smart material technology meets fluid dynamics. SMAs are exceptional due to their thermomechanical properties, like the shape memory effect and pseudo elasticity, which originate from their unique crystallographic structure.

This structure transitions between two phases: martensite at low temperatures and austenite at high temperatures. The transition is key to producing high-performance, solid-state actuators that are completely silent in operation.

On this page you will find:

- Our product range

- Historical discovery and evolution of shape memory alloy valves

- Dolphin Fluidics' shape memory alloy valves advantages

- Applications across industries

Molla SMA from Fluid-o-Tech on Vimeo.

Our shape memory alloy valves product range

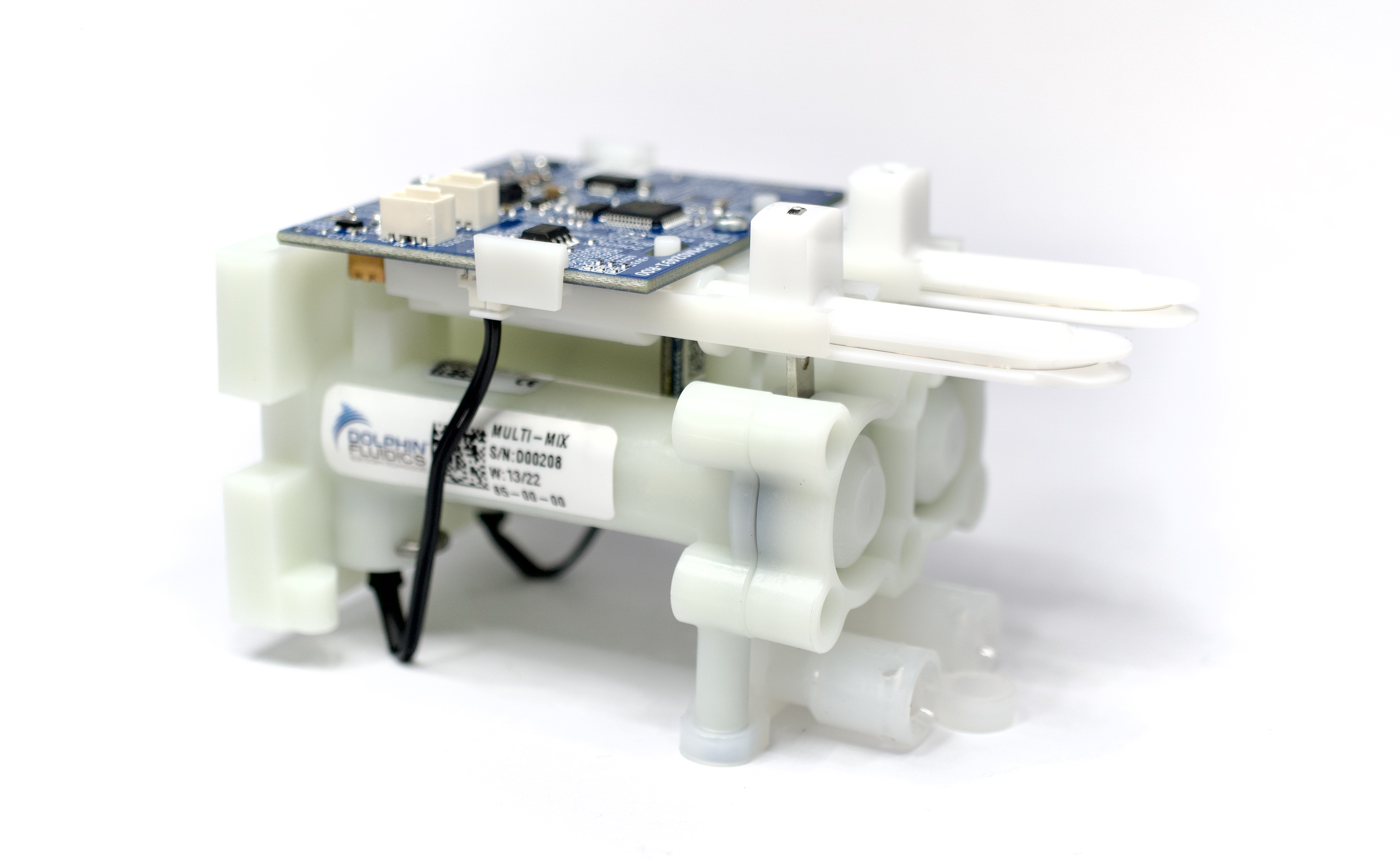

Dolphin Fluidics valves are designed as mechatronic products, integrating a single device with actuation based on shape memory alloys, microprocessor electronics for closed-loop flow control, and an IoT communication module for remote management and data transfer. Each product is smart, as it is capable of being controlled through dedicated firmware and connected to cloud systems and mobile platforms. Utilizing ultra-fine SMA wires ranging from 100 to 200 microns in diameter, Dolphin Fluidics’ valves operate without the mechanical components found in traditional systems and so achieving compactness, energy efficiency and precision.

Here are some of our smart valves that include shape memory alloy actuators.

Smart HP Liquid valve

The Smart HP Liquid Valve, a 2-way, normally closed shape memory alloy technology valve, excels in dosing and dispensing liquids with unmatched precision. Its low power consumption—up to 20 times less than traditional valves—and silent operation, coupled with direct sensor interface capabilities, allow for meticulous control over fluid dynamics. Customizable to various needs, this valve is a cornerstone for applications demanding high accuracy and energy efficiency.

Digimed valve

Designed specifically for the healthcare industry, the dual-channel Digimed Valve from Dolphin Fluidics offers precision in managing liquids and gases through its two independent channels. This 2-way, normally closed shape memory alloy valve integrates seamlessly with external monitoring equipment to provide real-time flow adjustments.

Digipinch Valve

The Digipinch Valve employs shape memory alloy technology to achieve a pinch-type, normally closed configuration that ensures sterile liquid handling without contact. Its innovative actuation method allows for precise pressure adjustments within the tubing system, ensuring accurate fluid dosing. Like other Dolphin products, it features low power usage and silent operation, with comprehensive customization options to tailor its functionality across various industries.

Digisense Shape Memory Alloy Valve

The Digisense Valve represents the pinnacle of Dolphin Fluidics' innovation, incorporating dual independent channels equipped with temperature probes and flowmeters. This setup facilitates exact mixing and dosing, even of fluids with varying viscosities, by controlling outlet temperatures with high precision. Designed as a fully integrated system, this shape memory alloy valve operates quietly and efficiently, requiring no external components for its operation and allowing for extensive customization to meet diverse application needs.

On/Off valve

Efficient and straightforward, the On/Off Valve is ideal for simple dispensing and mixing tasks in food and beverage applications. It leverages advanced technology to provide reliable, easy-to-integrate solutions for routine processes.

EAV Valve

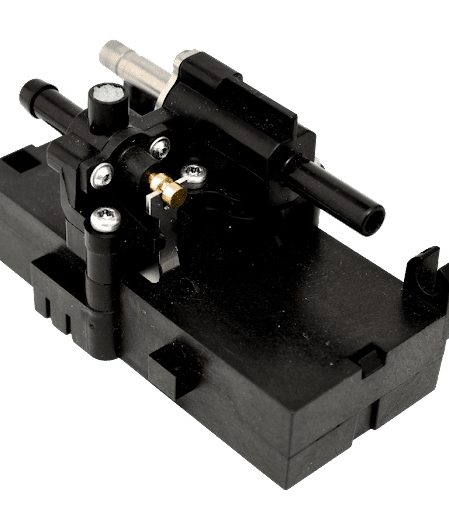

Dolphin Fluidics EAV valves are 2-way, normally closed, full-separation valves for accurate dosing, mixing and dispensing of liquids and gases. The Air/Gas/Vapour Smart valve has two independent channels; channel 1 proportionally controls an air flow, channel 2 proportionally controls vapour or liquid.

Antivacuum valve

The antivacuum thermostatic valves series are able to restore the atmospheric pressure inside a biphasic closed system in an extremely precise and reliable way. At the same time, they also act as air vent valve during the heating phase. The key element of the project is a new intelligent actuator system made of a shape memory alloy. According to the temperature it is subjected to, the system is capable of reacting to the heat without any further energy source. Compared to the traditional systems, it does not require any electrical power and can be installed in any position and orientation.

Mixing valve

These mixing valves for professional coffee machines are capable of delivering hot water for the preparation of infusions at the desired temperature and with a high degree of accuracy and stability.

Each product from Dolphin Fluidics not only represents the forefront of SMA valve technology but also delivers on the promise of innovation, customization, and excellence. Embrace the future of fluid control with Dolphin Fluidics' Shape memory alloy valves.

Find out more about our technology

Historical discovery and evolution of shape memory alloy technology

The journey of SMA began in 1932 with the discovery by American scientists Chang and Read, who first noticed these properties in a gold-cadmium alloy. The breakthrough came in 1963 when William Buehler discovered the same characteristics in a nickel-titanium alloy at the U.S. Navy's Naval Ordinance Laboratories, leading to the development of NiTiNOL.

Dolphin Fluidics shape memory alloy valves advantages

Utilizing ultra-fine SMA wires ranging from 100 to 200 microns in diameter, Dolphin Fluidics’ valves operate without the mechanical components found in traditional systems, offering several advantages:

- Compact and lightweight: The actuators are minimal and light.

- Energy efficiency: Consuming less than 3W of power.

- Silent operation: They operate silently, making them ideal for environments where noise is a concern.

- Precision and control: Feedback-controlled actuation ensures precise fluid handling.

Applications across industries

SMA technology has found its applications in various sectors:

- Mechatronics and thermotechnology: For manufacturing devices that integrate sensors and actuators, like smart valves.

- Biomedical: Used in orthodontic wires, coronary stents, and surgical instruments.

- Commodity sector: Notably in super elastic eyeglass frames.

Want to know more about our shape memory alloy technology?

Contact usContact request

Thank you for your interest Error processing your request. Please retry or contact us.

)